Technology and innovation

Technology and innovation to change Milan's sustainable mobility

Milan’s M4: the smart, driverless and green metro line

Milan’s new M4 Metro not only ensures high levels of environmental sustainability, but it is also a fully automated light railway. It retains the characteristics of the classic underground but with higher and less costly technical standards. The M4 is an entirely underground and fully automated line, a driverless line, with aroute that runs from thr Linate airport to the Milan San Cristoforo station. Crossing Milan's historic centre, it allows rapid travel along the east/south-west route of the city and a significant reduction in road traffic.

The M4 Metro’s driverless technology: efficiency and safety

Milan's M4 metro line is built with driverless technology. It therefore does not require the presence of a driver on board. This innovative transport model has already been used in very significant projects. The driverless lines built or under construction by the Webuild Group include Cityringen in Copenhagen; line C in Rome; the new Riyadh metro; and the Grand Paris Express in Paris.

The main benefit of the new driverless lines is that the operating schedule can be varied, i.e., the number of trains in action can be changed based on public demand. This ensures greater operating efficiency linked to varying the frequency of services, higher safety standards at the stations and lower operating costs as there is no driver.

With regard to the M4 specifically, the close frequency of trains is possible thanks to the driverless technology that allows trains to communicate with each other through a Wi-Fi network. Therefore, each convoy knows exactly at what distance the previous or the next one is, approaching without risk of accidents. This state-of-the-art system allows Milan’s new M4 Metro line to transport 24,000 passengers per hour in each travel direction.

Know-how and cutting-edge techniques for the M4

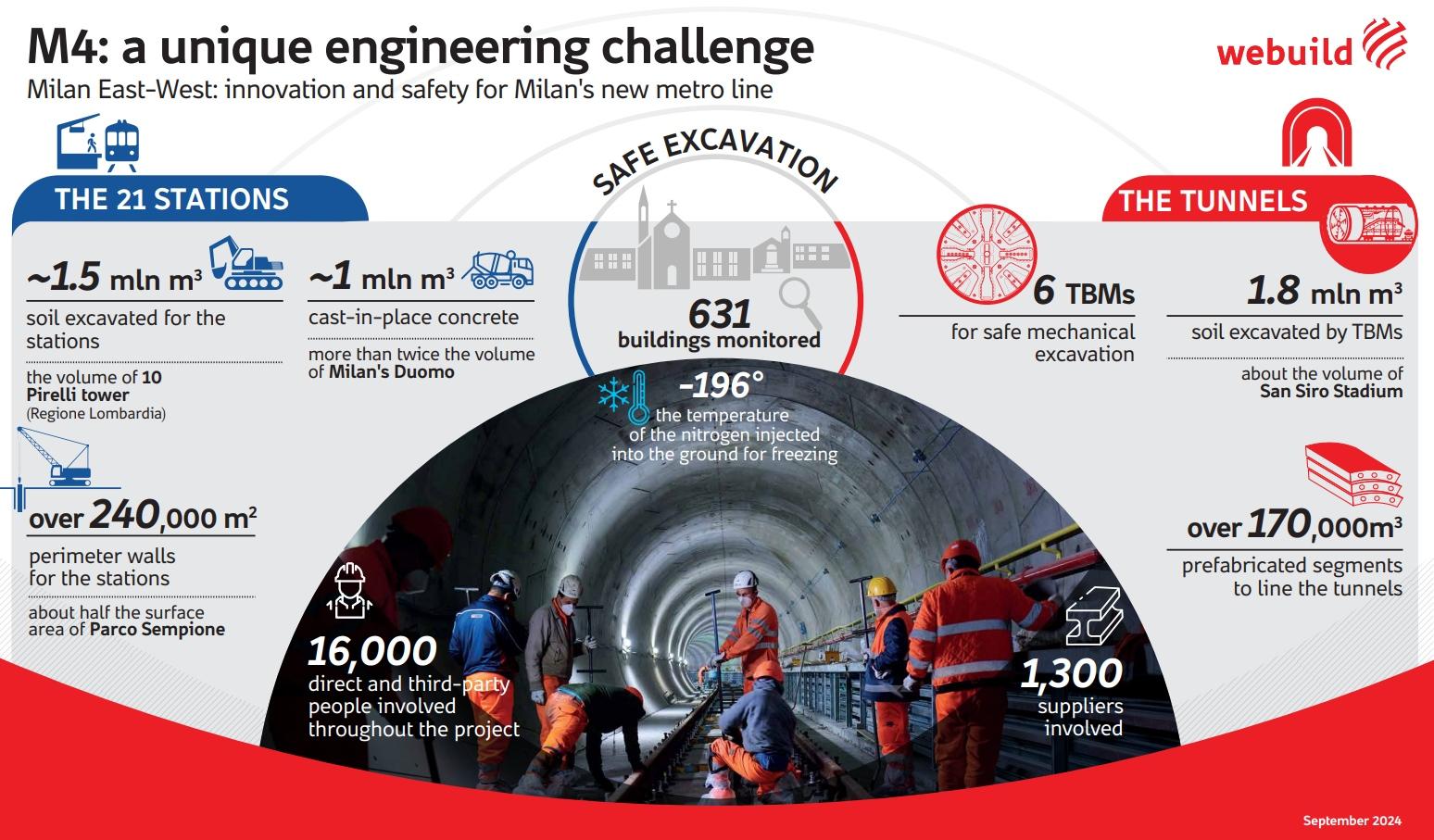

The construction of the M4 was a complex engineering project, requiring state-of-the-art technologies and specific expertise. The tunnels were excavated with six TBMs (Tunnel Boring Machines) that dug at an average depth of 20m from road level, up to a maximum of 30m.

Soil consolidation was achieved through two techniques: jet grouting, a method involving the injection of cement mixtures to stabilize the soil and prevent seepage; and artificial soil freezing, another state-of-the-art technique used in the construction of the M4 tunnels, which prevents subsidence during excavation. This technique involves freezing groundwater through the use of liquid nitrogen at -196° and makes the soil compact like a rock, facilitating excavation.

The challenges of M4 - High Technology in the center of Milan

The challenges of M4 - Ground freezing

Safe, sustainable mobility for citizens

Milan’s new M4 Metro line has doors that open automatically at the platform, which guarantees high safety levels for passengers entering and exiting the trains. The doors consist of a fixed frame, sliding doors and emergency exit doors.

The sliding doors are equipped with an emergency opening mechanism that also allows manual opening from the track. This allows passengers an emergency exit from the train to the platform if the vehicle is aligned with normal stopping tolerances.

Milan's M4: sustainable mobility serving the city

Milan’s M4 Metro is a unique work, in mobility, environmental andsustainability terms, which strengthens the Lombard city’s ecological footprint. It also brings significant environmental, economic, and collective benefits. Milan's M4 is able to transport 86 million people, every year.